O carboneto de silício (SiC) como material semicondutor de alto desempenho, devido às suas excelentes propriedades físicas e químicas, em eletrônica de potência, microondas de radiofrequência, optoeletrônica e outros campos apresentam grande potencial de aplicação. No entanto, a alta dureza e a estrutura estável do carboneto de silício representam grandes desafios ao seu processo de polimento. Este artigo enfocará as razões da dificuldade de polimento de substrato de carboneto de silício, a fim de fornecer referência para pesquisa e aplicação em áreas afins.

Primeiro, alta dureza e fragilidade causadas por problemas de polimento

A dureza ultra-alta do carboneto de silício é uma de suas características notáveis, e a dureza Mohs é de até 9,5, perdendo apenas para o diamante. Esta característica de alta dureza torna necessário o uso de abrasivos e ferramentas de dureza igualmente alta no processo de polimento. No entanto, abrasivos de alta dureza muitas vezes levam ao rápido desgaste das ferramentas de polimento durante o processo de polimento, o que não só reduz a eficiência do polimento, mas também pode levar a um declínio na qualidade do polimento. Além disso, a fragilidade do carboneto de silício também é um grande problema no processo de polimento. No processo de polimento, o substrato de SiC está sujeito a rachaduras, formando danos superficiais e rachaduras. Esses defeitos não afetam apenas a qualidade da aparência do wafer, mas também podem afetar seu desempenho elétrico e confiabilidade.

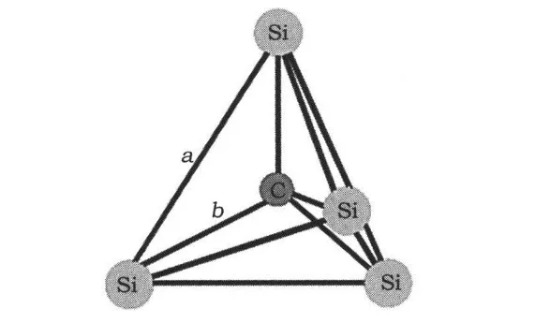

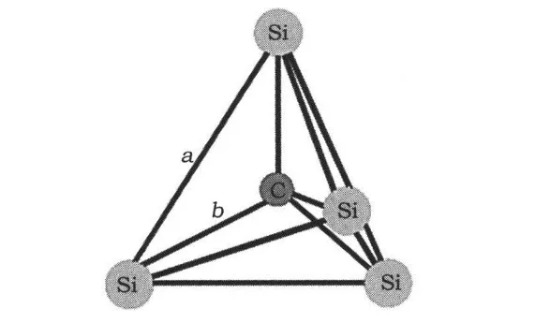

Em segundo lugar, o desafio de polimento trazido pela estrutura de treliça estável

A estrutura reticular do SiC é composta por tetraedros Si-C, que possuem uma estrutura compactada e alta estabilidade. Esta estrutura de rede estável torna extremamente difícil alterar a estrutura da superfície por meios de usinagem externos. No processo de polimento, para quebrar a ligação covalente entre os átomos de Si-C, para conseguir a remoção do material e a melhoria da qualidade da superfície, é necessário consumir muita energia térmica e força de cisalhamento por fricção. Isso não só aumenta o consumo de energia e o tempo gasto no processo de polimento, mas também pode causar danos à estrutura interna do chip.

Terceiro, o impacto do estresse no processo de polimento

No processo de polimento tradicional, a peça e a matriz de polimento são geralmente fixadas com cola. No entanto, devido ao coeficiente inconsistente de expansão térmica entre o substrato de SiC e a matriz de polimento, ocorrerá tensão no local de ligação após o resfriamento e a cura. Estas tensões afetarão negativamente a forma e o acabamento da superfície do wafer durante o polimento, resultando em um declínio na qualidade do polimento. Além disso, o calor de fricção e o estresse mecânico gerado durante o processo de polimento podem agravar ainda mais esse efeito, tornando o processo de polimento mais difícil de controlar.

Quarto, a seleção do fluido de polimento e da almofada de polimento

O fluido de polimento e a almofada de polimento são os elementos-chave no processo de polimento e sua seleção afeta diretamente o efeito de polimento. Para substratos de carboneto de silício, devido à sua alta dureza e fragilidade, o fluido de polimento tradicional e a almofada de polimento são muitas vezes difíceis de atender aos seus requisitos de polimento. Por um lado, a composição do líquido de polimento, o tamanho das partículas e a concentração do abrasivo precisam ser controlados com precisão para evitar danos excessivos ao cavaco; Por outro lado, a dureza, a elasticidade e a topografia da superfície da almofada de polimento também precisam corresponder às características do substrato de carboneto de silício para obter o melhor efeito de polimento. Porém, fluidos de polimento especiais e pastilhas de polimento para substratos de SiC ainda são escassos no mercado, o que aumenta ainda mais a dificuldade e o custo do processo de polimento.

Em resumo, as razões para a dificuldade de polimento de substratos de carboneto de silício incluem principalmente sua alta dureza e fragilidade, estrutura de rede estável, a influência do estresse no processo de polimento e a seleção do fluido de polimento e da almofada de polimento. Estes desafios não afetam apenas a eficiência e a qualidade do polimento dos substratos de SiC, mas também limitam a sua aplicação e desenvolvimento em campos relacionados. Portanto, é necessário fortalecer a pesquisa e a inovação da tecnologia de polimento de substrato de carboneto de silício no futuro para superar esses problemas e promover a ampla aplicação e desenvolvimento de materiais de carboneto de silício.